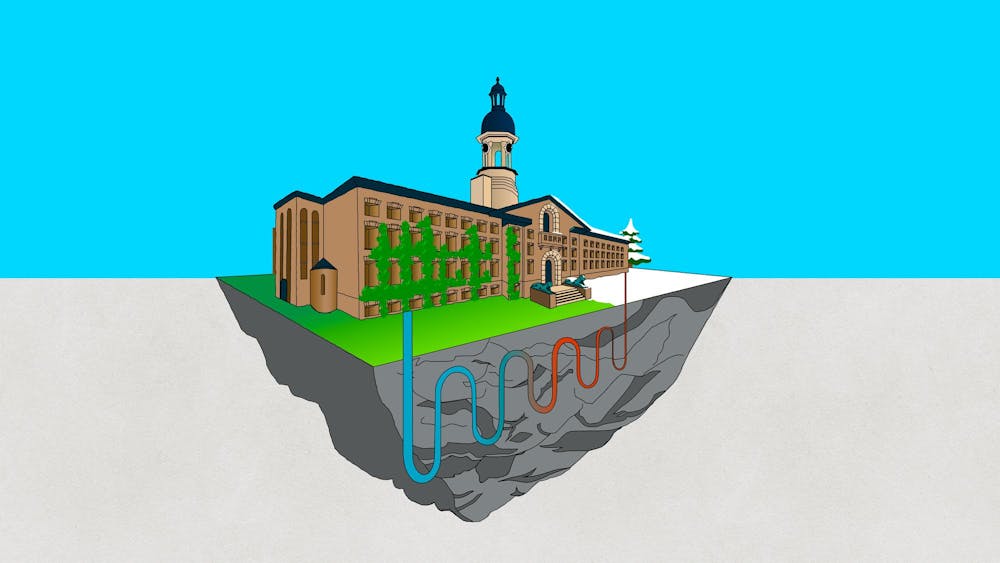

Remember your childhood piggy bank? You know, the one that sat on the edge of your bookshelf, swallowing your 25-cent-weekly allowance in its belly until it finally held enough to purchase your dream lego model? Scale that system up by 13 miles and you get Princeton’s geo-exchange. Instead of quarters, geo-exchange stores heat in a sprawling, mostly underground network of district hot water piping, to be released when needed.

Heat pumps and geo-exchange: a dream team for efficiency

For nearly two centuries, Princeton’s method of powering campus, known as cogeneration, would have wasted the heat of warmer months in New Jersey. Cogeneration, also called Combined Heat and Power (CHP), involves burning natural gas to produce both heat and thermal energy.

Built in 1996, the Princeton Energy Plant provided a more efficient alternative to coal, squeezing as much power as possible from a gas turbine engine by capturing the hot exhaust and using it to pre-heat water before it enters the boilers.

Though relatively efficient and cleaner than coal, this combustion-based process still releases carbon dioxide into the atmosphere. Burning natural gas creates hot steam, which is then sent through pipes at 450 degrees Fahrenheit. In order to meet its goal of net-zero carbon emissions by 2046, the University needed to find a way to continue meeting campus energy demand while eliminating combustion.

This brought about heat pumps and geo-exchange. Together, these two technologies store the summer heat, which the cogeneration had not been utilizing, and return it during the winter. Energy Plant Director Dave Weis explained that this process is already underway this winter season. “We’ve got a good amount of heat from over the summer, and we’re continuing to withdraw it right now from the field,” he said in an interview with The Daily Princetonian. “So if you’re warm and cozy as you read this, and you happen to be in one of the newer buildings already converted to the hot water system, you have a whole lot of rock and underground pipes to thank.”

Geo-exchange is more efficient than cogeneration for a number of reasons. The cogeneration method is around 70 percent energy efficient. That means that “if we’re burning 100 units of energy, we’re getting the benefit out of 68, and 32 are lost,” according to Weis.

This is not bad by energy standards, but heat pumps perform better. Rather than using a chemical reaction to change the state of matter into thermal energy, they simply move heat from one place to another. Employing the same basic principle as an air conditioner or a refrigerator, it only takes one unit of energy to move five units of heat. “It’s the magic of the refrigeration cycle,” said Sarah Boll, executive director of the Office of Sustainability, in an interview with the ‘Prince.’

Additionally, the heat pumps draw electricity from the grid to heat water rather than natural gas.

Geo-exchange also reduces Princeton’s water usage. While cogeneration and chilled water operation require an input of water from an outside source, geo-exchange recirculates the same water between the geo-exchange fields and the heat pump plant in a closed loop system.

By relying on seasonal cycles, geo-exchange is distinct from geothermal energy, which involves extracting pre-existing heat from the ground, and allowing it to escape back into the atmosphere. Weis emphasized that geo-exchange is not extractive.

“I think that the thermal piggy bank is a great way to describe geo-exchange,” said Weis. The bank is the bedrock beneath campus, transformed into a vast battery that stores heat until it’s needed. The temperature of the rock beneath campus will increase from about 57 degrees to 80 degrees Fahrenheit alongside the boreholes, according to a video produced by the Office of Sustainability featuring Andlinger Center Professor Forrest Meggers and former Energy Plant Director Ted Borer.

Though summer is often associated with the need for cooling, some areas of campus, such as domestic hot water and some lab spaces, still require heat. “We get the humidity in the air just right, and then we warm it back up until the temperature is just right, and then it satisfies the needs of all the experiments and research that’s happening,” Weis said. “Even in the summer, we need some heating to run our buildings and support the University mission.”

In the winter, the opposite can be true. Though heat is in high demand, particular server rooms and research equipment require heat to be pulled out. “There is always some amount of simultaneous heating and cooling needed on campus,” Weis explained. Still, geo-exchange takes advantage of the natural seasonal imbalance to capture and recover energy that might otherwise be lost.

Geo-exchange is just one component of Princeton’s greater net neutrality goals. The “steam to hot water and geo-exchange” conversion represents around 40 percent of the Office of Sustainability’s graphic depicting the plan, with the other most significant chunk being renewable electricity.

Boll emphasized the relationship between these components. “Through the conversion to high temperature hot water supplied by heat pumps, we’re essentially electrifying campus,” Boll explained. “Once we can supply renewable energy to all of campus, through one flavor of renewables or another, that’s really when we’re going to achieve both of these wedges together.”

However, Weis and Boll both warned that more sustainable energy is not a license to waste it. “Close your fume hoods, take shorter showers, keep your windows closed, close the door,” Weis said.

An enormous structural undertaking

In 2021, Princeton began the process of drilling over 2,000 boreholes on campus, each 600 to 850 feet deep. Some of these are tucked away beneath the East Garage and the Meadows softball field, but others are in more prominent places on campus, such as under Poe Field and Whitman Lawn.

Each hole houses a vertical pipe five to six inches in diameter, filled with a narrow high density polyethylene tube and grout through which water flows. The pipes form a closed-loop system, meaning the water never actually comes into direct contact with dirt or rock. Rather, heat is transferred to and from the bedrock via conduction.

Keeping all this water flowing at the right temperature led to the construction of two new facilities: the Thermally Integrated Geo-Exchange Resource “TIGER,” located on Broadmead Avenue, and the Central Utility Building “CUB” over in the new Meadows neighborhood.

These plants were built with continued expansion in mind. “Right now in TIGER, there’s space for two more heat pumps. In CUB, there’s space for three more,” Weis said. Additionally, the current capital plan is matched with the geo-exchange construction, so heating and cooling can meet campus demand.

Linking the system with each building on campus is no easy feat, especially for some of Princeton’s centuries-old buildings. To convert any building, all of the piping and the HVAC parts in that building must be converted from steam service to hot water coils. That, and the fact that Princeton is a full-time academic institution, can make installation challenging.

As of now, 25 buildings in total have been converted to use geo-exchange, Weis wrote to the ‘Prince’ in an email. Most are newer structures, such as Yeh and New College West, as well as engineering and athletic buildings. Five additional buildings have been partially converted but still use some steam. In total, this represents about a million and a half square feet already converted from steam to hot water.

Up next for conversion are six relatively new campus buildings, which will be on hot-water from day one of operation: the Art Museum, ES & Commons, SEAS, Frist Health Center, Hobson, and Schmidt Hall. The University plans for all of campus to be eventually converted, and Princeton’s means of heating, cooling, and for electricity production to become almost completely combustion-free.

Operating the new systems

A team is necessary to generate heat-power. Richard Phillips, one of three lead engineers at the plant, started at Princeton as an apprentice in 2010 and has seen the system transform over the course of his time at the University. All of the systems, including TIGER and CUB, can be operated via the bright, screen-dominated control room in the West Plant.

Phillips’ favorite part of the job is “the unknown,” he said in an interview with the ‘Prince.’ “We’ve been trained for it, we try to look out for certain trip-ups, and we try to be as prepared as we can,” he added.

There is an operator on shift at the plant 24 hours a day, 365 days a year, to troubleshoot in real time.

Phillips also appreciates that Princeton is not relying on artificial intelligence to make decisions, but instead values “human element of operations.”

For many years, Phillips was accustomed to operating the cogeneration and chilled water plant. “I’ve always been drawn to it … I think I understand it best. The new stuff, the geo, the heat pump supplier, it’s completely new for us, for everybody,” he explained.

This has resulted in a steep learning curve for the engineers and operators. “You’re so ingrained in energy transfer in a power plant. The wasted heat goes out of a cooling tower. And now we’re gonna take that heat, and use it with the geo. It seemed like magic,” Phillips said.

As of now, Princeton has three apprentices through the program in partnership with the Local 68 International Union of Operating Engineers, who work Monday to Friday from 7 a.m. to 3 p.m. in a maintenance driven role, rotating between the three plants.

Though there will likely remain some cogeneration capacity on campus reserved for emergency situations, Phillips described the replacement of cogeneration boilers with heat pumps as bittersweet. “It’s a sad goodbye. We’ve hung our hat on our steam plant for a long time. But I think the excitement outweighs the sadness for me,” he said.

Raphaela Gold is a head Features editor for the ‘Prince.’

Please send any corrections to corrections[at]dailyprincetonian.com.

A previous version of this piece said that the referenced video was produced by Professor Forrest Meggers and former Energy Plant Director Ted Borer. In fact, the Office of Sustainability produced the video. Meggers and Borer were featured in it. The ‘Prince’ regrets this error.